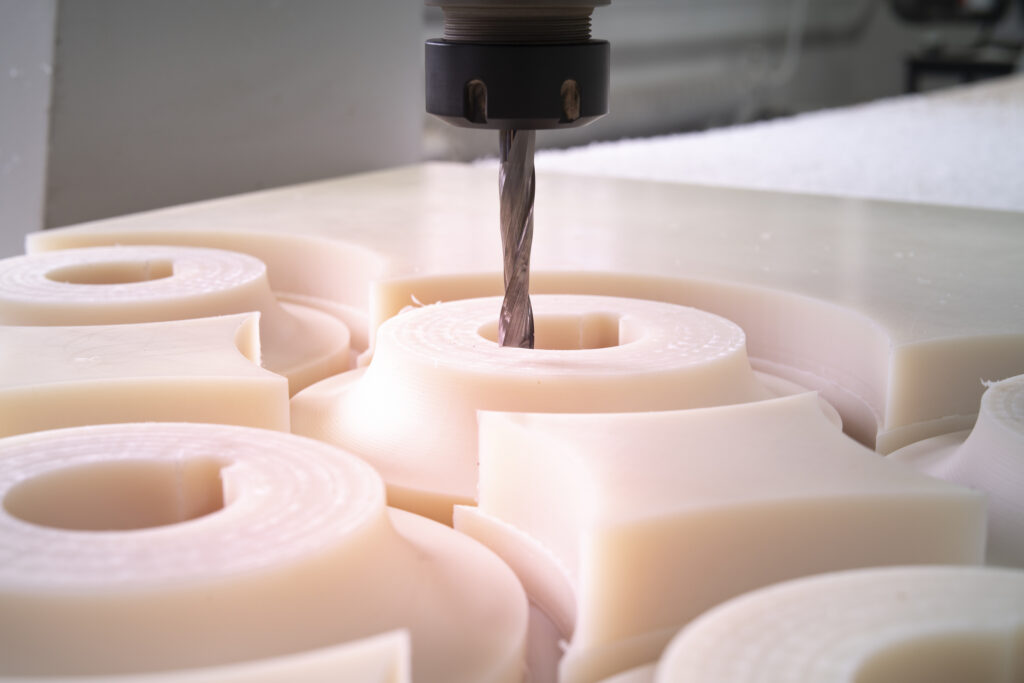

CNC Milling

Our CNC milling service offers precision, versatility, and quality. Whether it's complex details or large production batches, our experienced team and state-of-the-art equipment can meet your milling needs.

Our CNC milling service offers precision, versatility, and quality. Whether it's complex details or large production batches, our experienced team and state-of-the-art equipment can meet your milling needs.

CNC milling is a precise and automated machining method used for processing various materials such as metal, wood, or plastic. This process utilizes computer numerical control (CNC) to program the milling machine for cutting desired shapes and dimensions accurately.

The advantages of CNC milling include high productivity, repeatable precision, the ability to cut complex shapes and details, and the capability to work with various materials. It is ideal for prototyping, production automation, and manufacturing customized parts.

Milling requires detailed programming for the machine to perform the desired machining operations. In programming, specialized CAM software is used to create 3D models, generate toolpaths, make tool selections, and define machining parameters. The program needs to be inputted into the machine for it to accurately follow the prescribed machining procedures. Programming requires skills and knowledge in using CAD/CAM software and understanding machining processes.

The precision of CNC milling can range from a few hundredths of a millimeter to a few micrometers, depending on the machine and the machining task. This allows for the production of high-quality and precisely fitting components.

Materials:

- Metals: For example, aluminum, steel, stainless steel, copper, brass, and titanium are popular choices. Metals are popular choices because CNC milling can achieve precise dimensions and surface quality.

- Wood: Including particle board, plywood, oak, beech, pine, and many more. Wooden processed details can be both functional and decorative, finding applications in the furniture and construction industries.

- Plastics: For example, acrylic (PMMA), polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), and polycarbonate (PC). CNC milling of plastic parts is a widely used choice as it allows for the fabrication of complex shapes and structures.

- Composite materials: For example, carbon fiber composites and fiberglass composites. CNC milling is also beneficial for processing composite materials, which are commonly found in the manufacturing of aerospace, automotive, and sports equipment.

Processing options:

- Surface milling: CNC milling enables precise and smooth processing of various surfaces, including flat surfaces, curved surfaces, and complex contour milling.

- Groove cutting: CNC milling allows for cutting grooves of varying width and depth, which can be straight or curved. This is useful, for example, in creating channels, ribs, or intricate textures.

- Drilling holes: Using CNC milling, you can precisely drill holes of various diameters. This enables fast and accurate hole creation, whether they are straight or slanted.

- Milling complex 3D shapes: CNC milling enables the machining of complex 3D shapes, such as sculptures, intricate details, and reliefs. This opens the door to creative design and precision detailing.

- Surface finishing: CNC milling can also involve various surface finishing techniques such as grinding, polishing, and engraving. This allows for achieving the desired final result and surface quality.

Applications:

- Mechanical engineering: CNC milling is an essential tool in the field of mechanical engineering. It is used for the manufacturing of various components and parts such as gears, housings, fasteners, etc.

- Electronics: CNC milling is a valued method in the electronics industry for the fabrication of electronic components such as connectors, sockets, panels, casings, and more.

- Furniture: CNC milling is beneficial in the furniture industry, enabling the production of precise cuts, grooves, and decorative details. It is used, for example, in the manufacturing of furniture components such as tabletops, chair backs, cabinet doors, and more.

- Automotive industry: CNC milling is utilized in the automotive industry in various ways, such as in the manufacturing of engine components, brake systems, dashboards, door panels, and more.

- Medical devices: CNC milling is used in the manufacturing of medical devices, such as implants, prosthetics, surgical instruments, and more. Precision and repeatability are especially crucial in the production of medical equipment.

- Art and design: CNC milling allows for the creation of complex and unique sculptures, reliefs, decorative elements, and more in the field of art and design. It provides artists and designers with the opportunity to bring their creative visions to life.

METAKO places great emphasis on precision and quality in CNC milling and provides customized solutions to meet the needs of our clients. Our experienced and qualified team ensures that the manufactured components precisely meet the clients' requirements and specifications and undergo rigorous quality control.