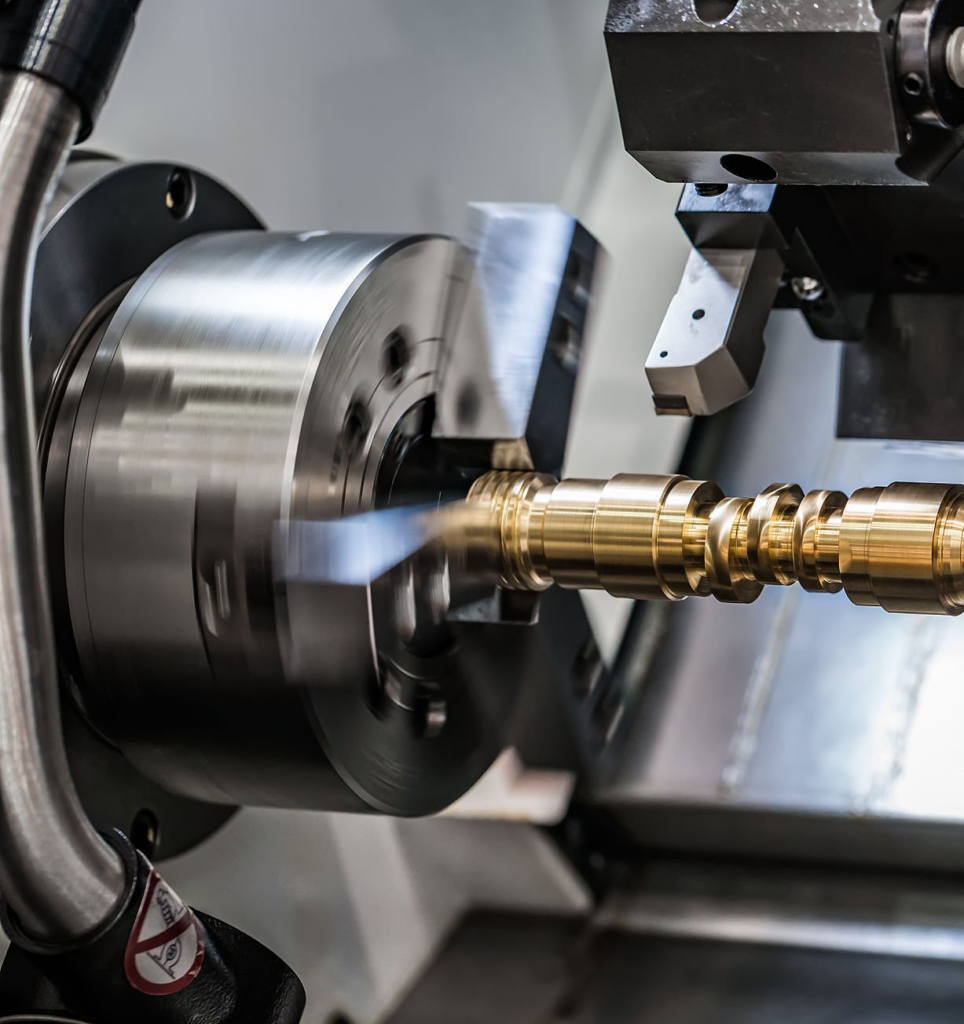

CNC Turning

The turning service we offer allows you to obtain precise and high-quality turned components. Our expertise in turning techniques and modern equipment ensure excellent results. We are your reliable partner for turning projects.

The turning service we offer allows you to obtain precise and high-quality turned components. Our expertise in turning techniques and modern equipment ensure excellent results. We are your reliable partner for turning projects.

CNC turning is a precise and automated machining method used for processing various materials like metal, plastic, or wood. This process utilizes computer numerical control (CNC) for programming the turning machine to achieve precise dimensions and shapes as desired.

CNC turning allows material removal according to a predetermined digital control program that governs the movement of the lathe and the cutting tool. This enables the production of complex components with high precision and repeatability. CNC lathes are capable of performing various turning operations, such as internal and external cutting, threading, drilling, chamfering, and more. It offers a wide range of possibilities for manufacturing different parts, including the potential for increased productivity compared to manual turning. This helps reduce production lead times and enhances a company's manufacturing capacity.

Materials:

- Metals: CNC turning allows for the machining of various metals, including aluminum, steel, stainless steel, copper, brass, and titanium.

- Plastics: CNC turning is an ideal method for processing various plastics, such as acrylic (PMMA), polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), and polycarbonate (PC).

- Wood: CNC turning enables the precise manufacturing of intricate details from various types of wood, including particleboard, plywood, oak, and pine wood.

Processing options:

- Turning surface textures: CNC turning allows for precise and smooth machining of various surface textures, including smooth surfaces, textured surfaces, intricate contours, and more.

- Machining holes: CNC turning allows for precise drilling of holes with different diameters, whether they are straight or at an angle. This enables fast and accurate hole creation.

- Machining complex 3D shapes: CNC turning enables the machining of complex 3D shapes, such as intricate details, sculptures, and reliefs, allowing for precise and intricate components to be created.

- Machining complex threads: CNC turning allows for precise threading, including internal and external threads on various components.

- Surface finishing: CNC turning can also involve various surface finishing techniques such as grinding, polishing, and engraving. This allows for achieving the desired final result and surface quality.

Applications:

- Mechanical engineering: CNC turning is essential in the mechanical engineering sector for the manufacturing of various components and parts such as shafts, gears, housings, and more.

- Electronics: CNC turning is used in the electronics industry for the manufacturing of electronic components such as connectors, sockets, panels, casings, and more.

- Furniture: CNC turning allows for the precise creation of cuts, grooves, and decorative details in the furniture industry.

- Automotive industry: CNC turning is used in the automotive industry, for instance, in the manufacturing of engine components, brake systems, dashboards, door panels, and more.

- Medical devices: CNC turning is used in the production of medical devices such as implants, prosthetics, surgical instruments, and more.

- Art and design: CNC turning allows for the creation of complex and unique sculptures, reliefs, decorative details, etc. in the art and design field. It gives artists and designers the opportunity to bring their creative visions to life.

METAKO specializes in CNC turning and has extensive experience in this field. Our team consists of experienced and qualified turning specialists who are well-versed in the use of various turning machines and tools and are trained in the latest technologies and processing methods. We work closely with clients to understand their machining needs and find the best solutions to achieve their goals. Our skills and expertise in CNC turning allow us to provide a wide range of turning services to various industries.

Precision and quality are of utmost importance to us. We ensure that the manufactured components precisely meet the clients' requirements and specifications and undergo thorough quality control. We utilize the best processing strategies and programming techniques to achieve optimal results and meet our clients' expectations.